Development of a coil sequencing tool for production facilities

- Visual Basic

Home » Success Stories »

Description

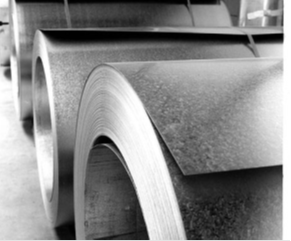

ArcelorMittal Sagunto has in its plant a set of lines for continuous or discrete processing of steel coils. The main lines are Pickling, Tandem, Galvanizing and Electrozincat. The sequence in which the coils enter has to be created taking into account a set of physical, quality, safety and commercial constraints. This is a complex process since the number of possibilities is very high. In scientific language we classify it as a combinatorial problem of the NP-hard type. The main objective of the project has been the construction of a tool for the automatic acquisition of the sequences This project has been done in several phases, in a first research phase a prototype was made to evaluate the ability to solve the problem. In subsequent phases, the problem was solved for each of the plant’s lines.